Carbide composite powder has become an essential material in the realm of high-performance industrial applications. Widely utilized in sectors such as aerospace, automotive, mining, and tooling, this advanced powder blend offers superior hardness, excellent wear resistance, and exceptional thermal stability. As industries continue to seek materials that deliver both durability and precision, carbide composite powders have emerged as a reliable solution for enhancing performance and longevity.

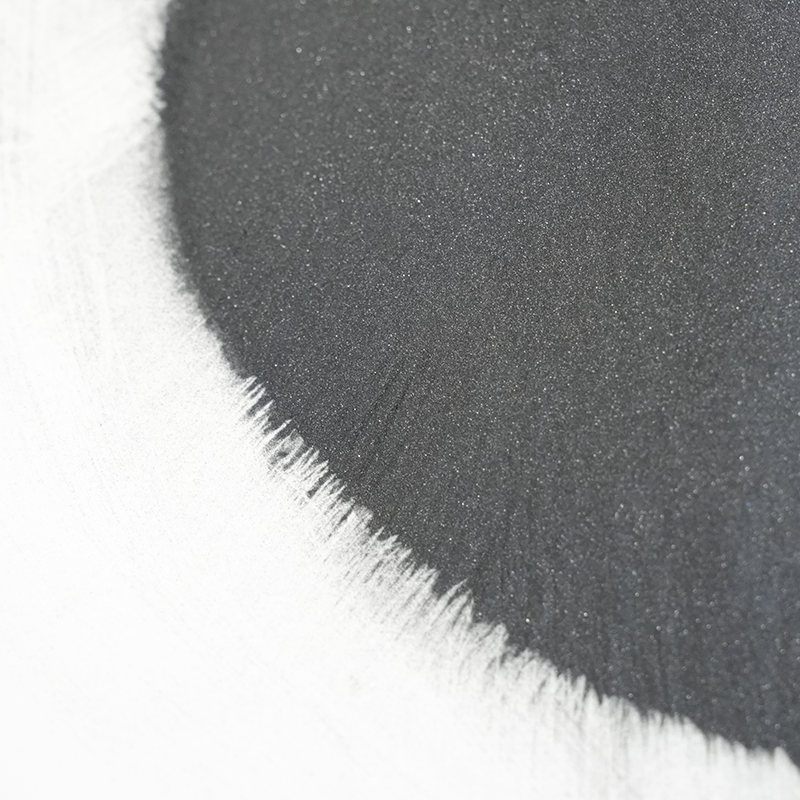

Carbide composite powder is a specially engineered blend of carbide-based particles, such as tungsten carbide (WC), titanium carbide (TiC), and other refractory carbides. These particles are often combined with metal binders like cobalt or nickel, creating a strong, wear-resistant material ideal for various high-stress applications. In simpler terms, carbide composite powder is a metal matrix composite that combines the best properties of metals and ceramics.

This powder is typically used in thermal spray coatings, powder metallurgy, and additive manufacturing processes. Because of its high density and toughness, it’s often selected for making cutting tools, wear parts, and corrosion-resistant components.

Key Advantages of Using Carbide Composite Powder

One of the most notable benefits of carbide composite powder is its exceptional hardness. The presence of hard ceramic phases like tungsten carbide gives the material superior abrasion resistance. This makes it ideal for environments where mechanical parts are subjected to repeated friction or impact.

In addition to hardness, carbide composite powder provides excellent thermal stability. It retains its mechanical integrity even at elevated temperatures, which is crucial in high-heat operations such as metal cutting, drilling, and mining.

Furthermore, this material showcases impressive corrosion and oxidation resistance, especially when nickel or cobalt binders are used. This makes carbide-based powders suitable for applications in harsh environments, including chemical plants and offshore drilling platforms.

Applications of Carbide Composite Powder

Carbide composite powders are widely used in industries where performance and reliability are paramount. Some common applications include:

Cutting tools: High-speed drills, end mills, and lathe inserts often rely on tungsten carbide composite powder for increased service life and efficiency.

Wear-resistant coatings: Thermal spray technologies use carbide powders to coat machine parts, reducing downtime and extending operational life.

Mining equipment: Rock drilling bits and excavation tools benefit from the superior durability of carbide-based composite powders.

Aerospace components: Jet engine parts and structural supports are coated or fabricated using carbide composites to withstand extreme conditions.

Synonyms and Variants in the Market

In the materials market, you might encounter synonyms or related terms like cemented carbide powder, hardmetal powder, or refractory metal composite powder. Though they may differ slightly in composition or processing method, these terms generally refer to materials that share the same core attributes—hardness, strength, and resistance to wear and heat.

Manufacturing and Customization

Manufacturers can tailor the composition of carbide composite powder to meet specific needs. By adjusting the ratio of carbides to binders or selecting different binder materials, the properties of the final product can be fine-tuned for applications such as die casting, forging, or high-precision machining.

Additionally, advances in powder metallurgy and additive manufacturing have increased the demand for customized carbide composite powders, offering greater design flexibility and reduced material waste.

English

English русский

русский عربى

عربى