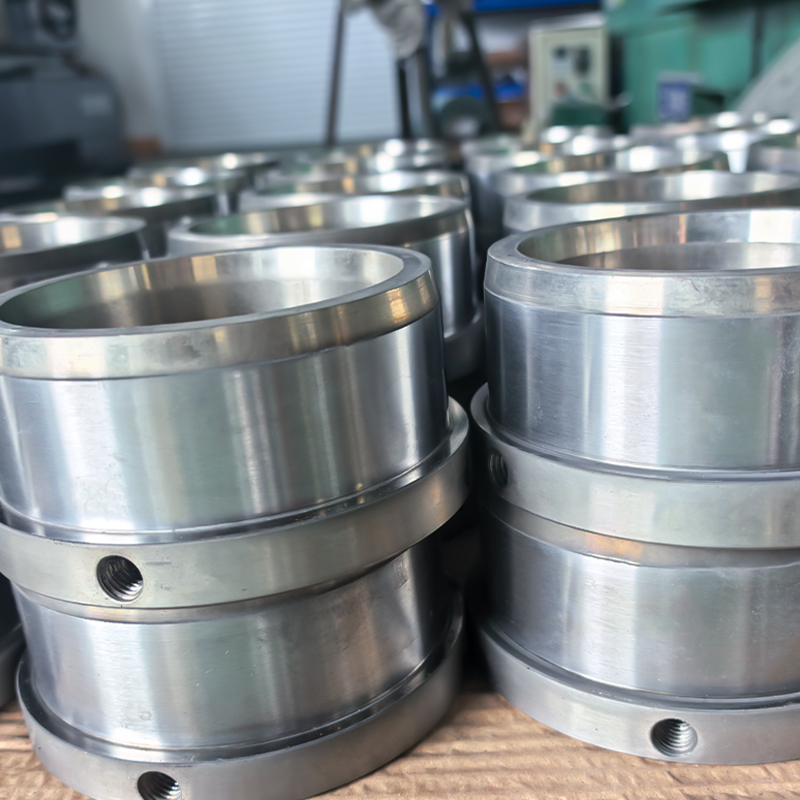

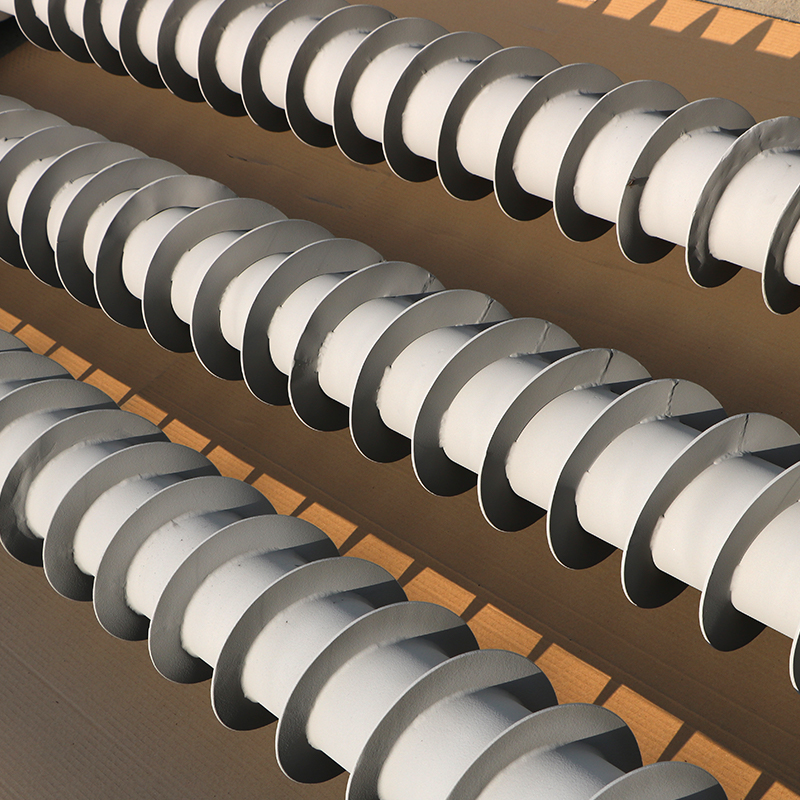

The bushings are customized products according to the drawings:

Base material: stainless steel 304, stainless steel 316, carbon steel, 45# steel optional.

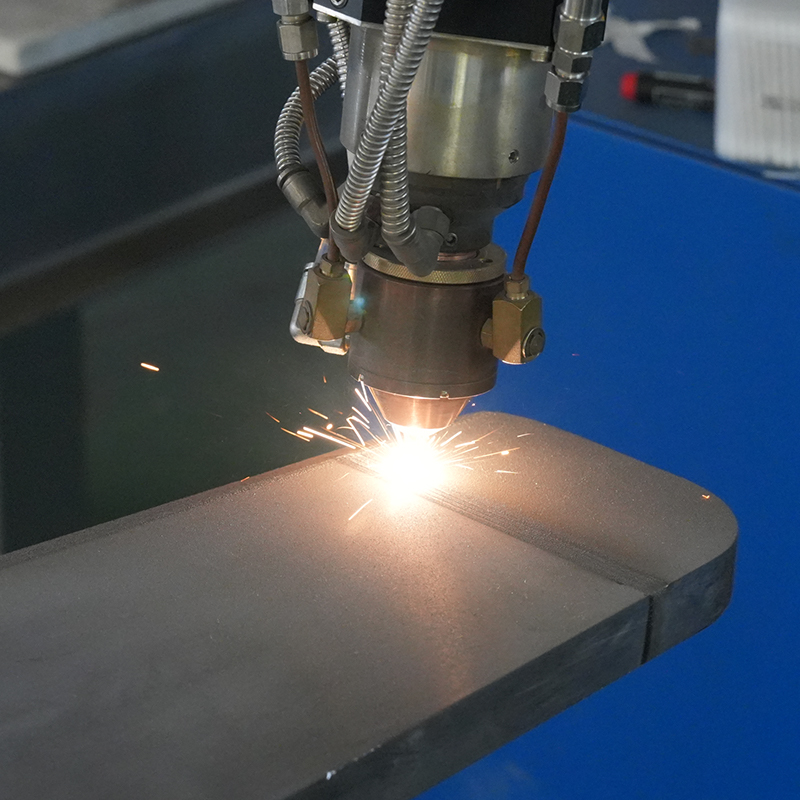

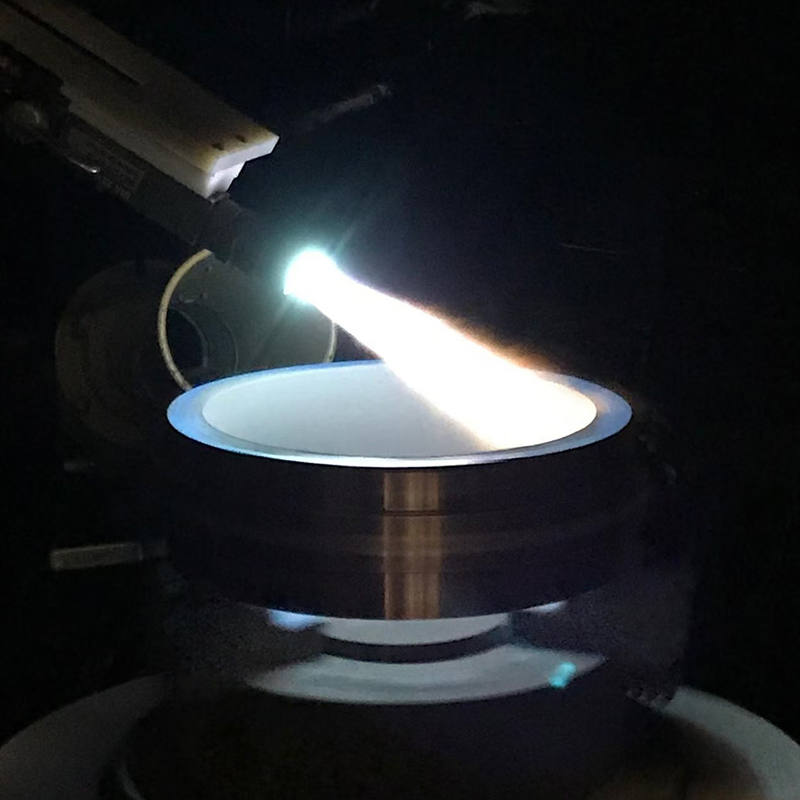

Second, the coating design: support customers to customize the production of drawings, according to the actual size of the bushing, the demand for working conditions to adjust the coating thickness (usually 0.1-0.3mm) and surface roughness, to ensure that the production of spraying and manufacturing can be installed directly after the use of the machine without the need for secondary processing.

Third, the choice of coating materials:

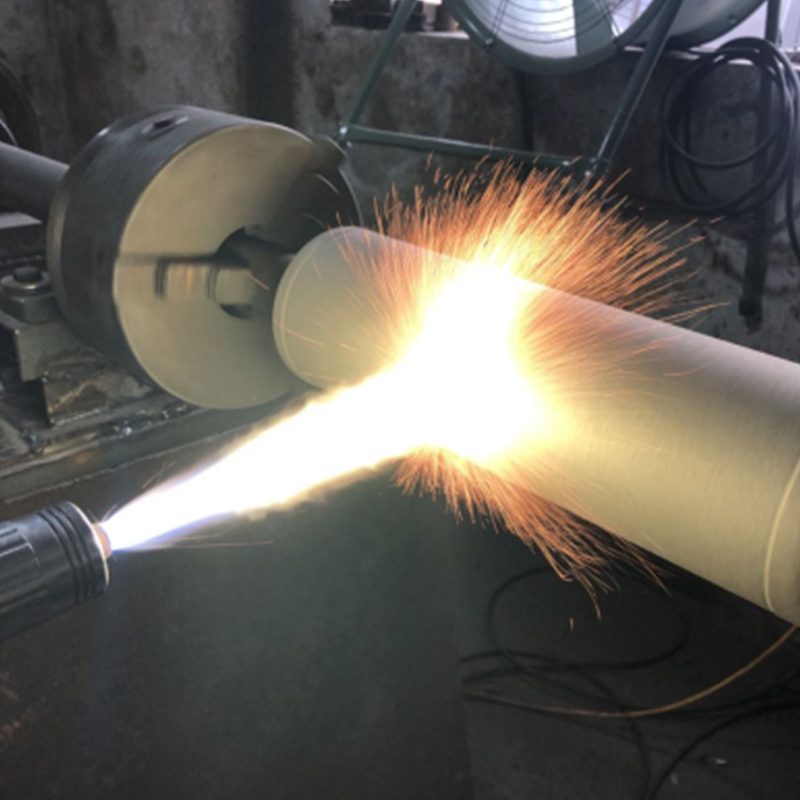

1、Can choose to surfacing Stellite alloy or spraying tungsten carbide coating

2、The combination process of Stellite alloy and tungsten carbide coating can be used to take into account the strength of the substrate and the wear resistance of the surface, avoiding the deformation and spalling problems caused by traditional welding or plating.

3, optional ceramic coating: ceramic chromium oxide chromium carbide coating (with corrosion resistance and high temperature advantages 800-1000 ° C, can be mirror processing), ceramic alumina coating (with corrosion resistance and high temperature)

Fourth, finishing:

1、Roughness after grinding: Ra0.8

2、Roughness after fine grinding and polishing: Ra0.02

Wear-Resistant Carbide Bushings Customized

Powder, (can be customized pure nickel powder, pure cobalt powder, pure copper powder, etc.) metal powder.

We are always committed to developing and producing various high-performance alloy materials for harsh environments, providing customers with high-strength, wear-resistant, corrosion-resistant and high-temperature-resistant alloy powders.

News

-

Industry News 2026-01-12

Core Characteristics and Chemical Composition of Cobalt-Based Alloy Powders Cobalt-based alloy powders, often referred to by the trade name Stellite in various industrial contexts, are sophisticated materials engineered ...

View More -

Industry News 2026-01-07

The Critical Role of Powder Morphology in Laser Cladding In the process of laser cladding, the physical characteristics of the powder are just as vital as its chemical composition. For a successful metallurgical bond and...

View More -

Industry News 2026-01-04

Understanding the Composition and Synergy of Carbide Composite Powders Carbide composite powder represents a specialized class of materials engineered by combining hard carbide phases, such as Tungsten Carbide (WC), Tita...

View More

English

English русский

русский عربى

عربى