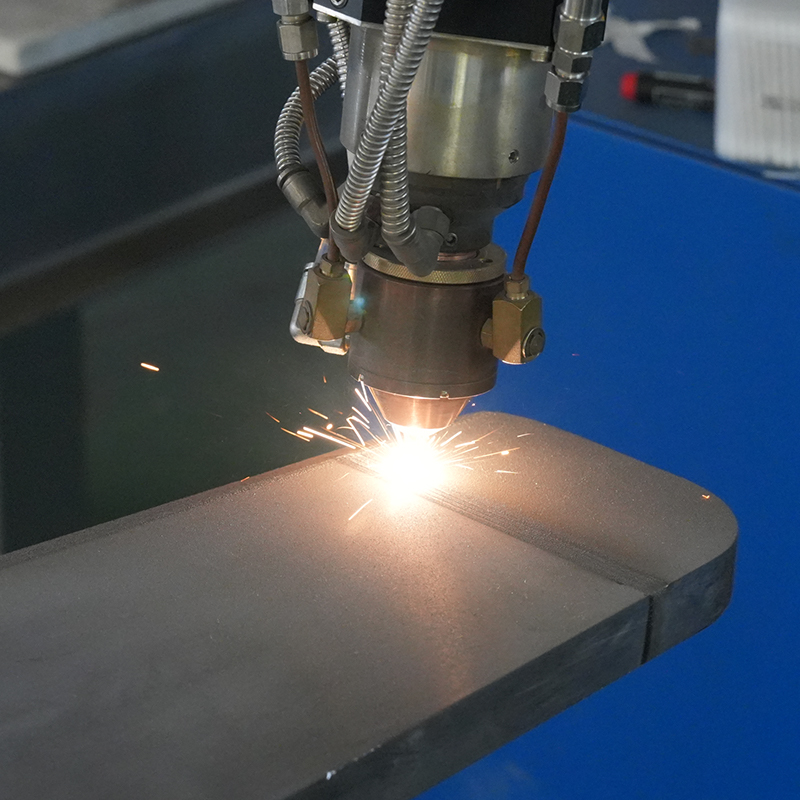

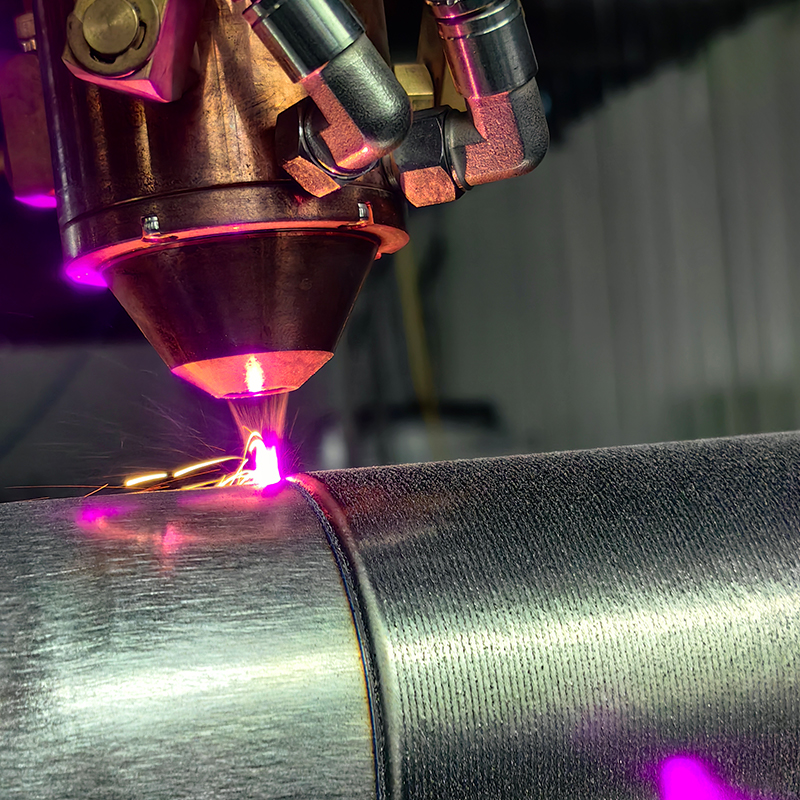

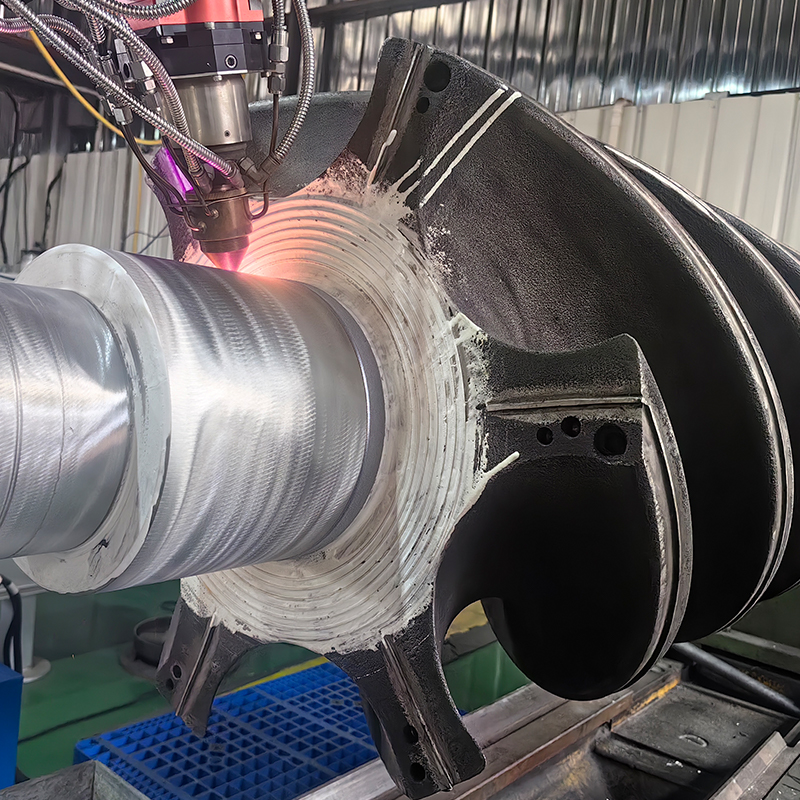

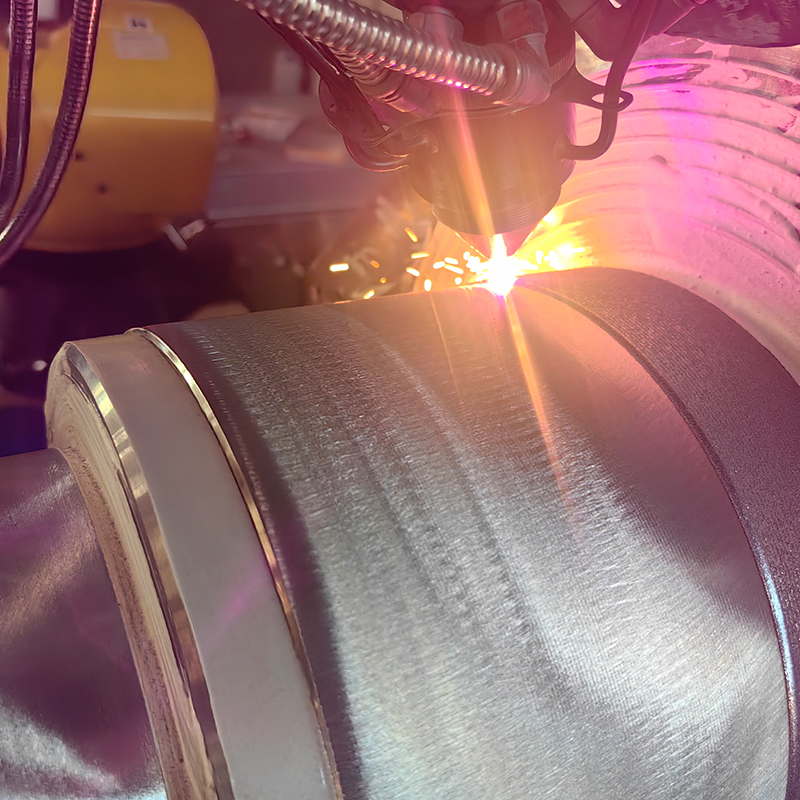

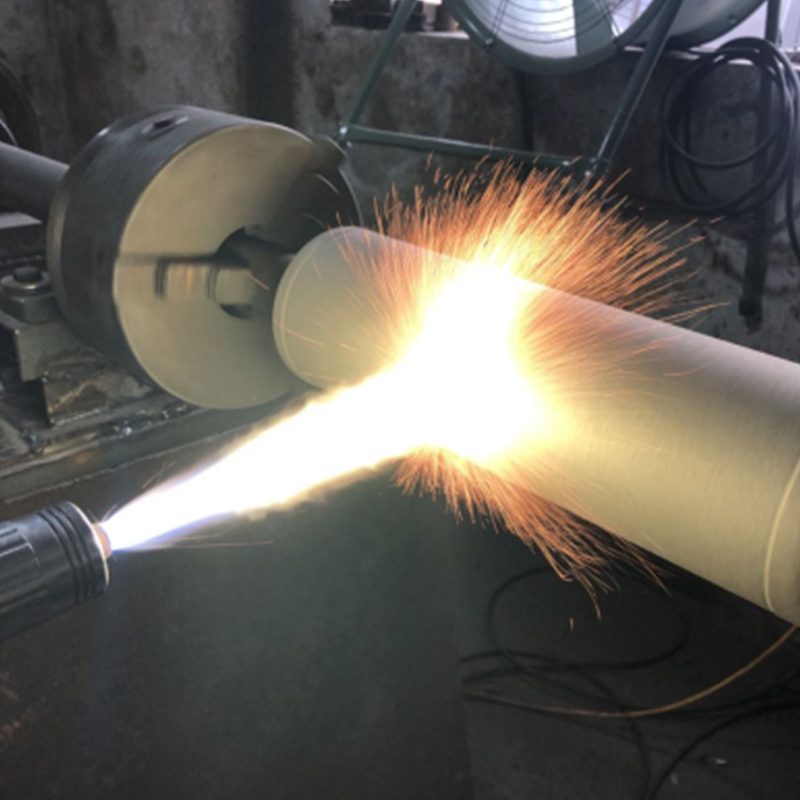

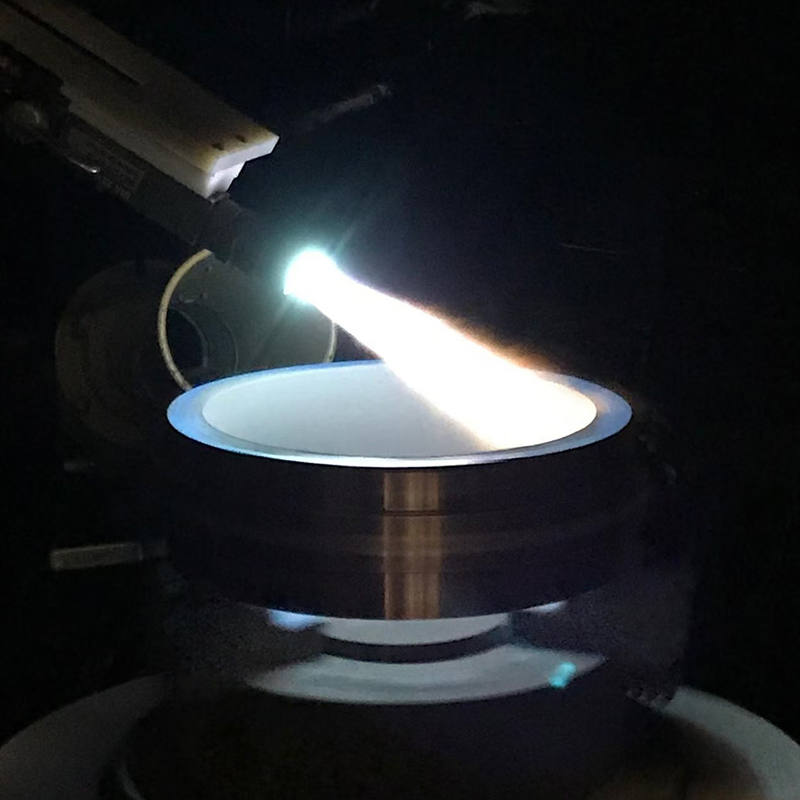

Laser Cladding, also known as laser deposition or laser cladding, is a new surface modification technology. It is a new surface modification technology, which forms a metallurgical additive cladding layer on the surface of the base material by adding the cladding material on the surface of the base material and using the laser beam with high energy density to make it melt with the thin layer of the surface of the base material.

Laser cladding features: low dilution of the cladding layer but the bonding force is strong, and the substrate is metallurgical bonding, which can significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant, or electrical properties of the substrate material surface, so as to achieve the purpose of the surface modification or repair to meet the material surface of the specific performance requirements at the same time to save a lot of material costs. Compared with surfacing, spraying, electroplating, and vapor phase deposition, laser cladding has the characteristics of small dilution, dense organization, good combination of coating and substrate, suitable for cladding materials, large changes in particle size and content, etc. Therefore, the application prospect of laser cladding technology is very broad.

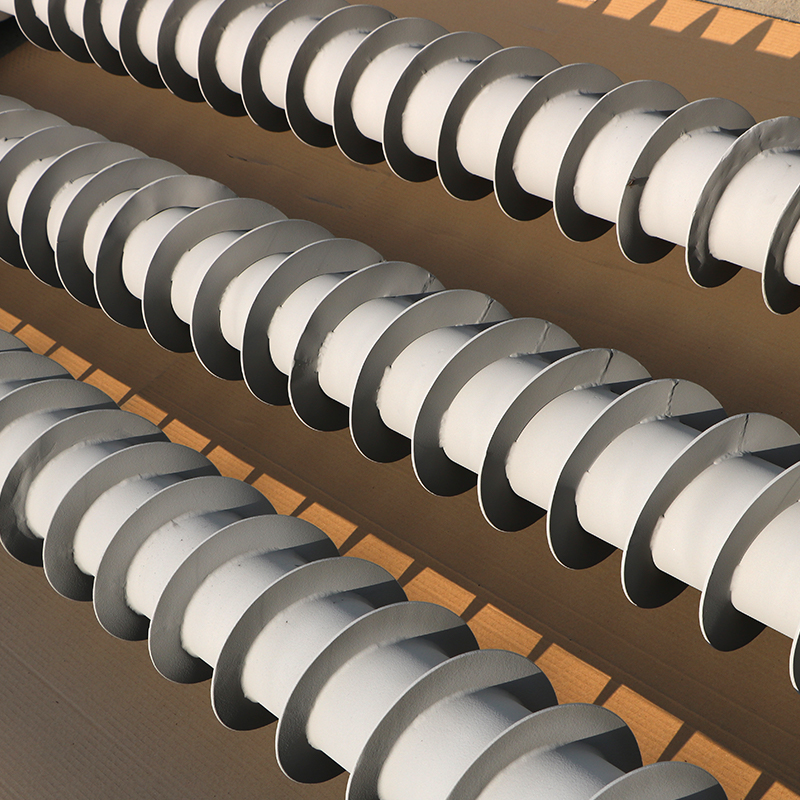

Coating materials: widely used laser cladding materials include: nickel-based, cobalt-based, iron-based, titanium alloys, copper alloys, granular metal matrix composites, ceramic materials, and so on.

Laser Cladding

Powder, (can be customized pure nickel powder, pure cobalt powder, pure copper powder, etc.) metal powder.

We are always committed to developing and producing various high-performance alloy materials for harsh environments, providing customers with high-strength, wear-resistant, corrosion-resistant and high-temperature-resistant alloy powders.

News

-

Industry News 2026-01-27

Understanding Carbide Composite Powder Carbide composite powder is a high-performance material widely used in industrial manufacturing due to its exceptional hardness, thermal stability, and wear resistance. Comprising f...

View More -

Industry News 2026-01-21

Core Characteristics and Advantages of Nickel-Based Powders Nickel-based metal powders are indispensable in modern engineering due to their exceptional ability to maintain structural integrity under extreme conditions. U...

View More -

Industry News 2026-01-12

Core Characteristics and Chemical Composition of Cobalt-Based Alloy Powders Cobalt-based alloy powders, often referred to by the trade name Stellite in various industrial contexts, are sophisticated materials engineered ...

View More

English

English русский

русский عربى

عربى