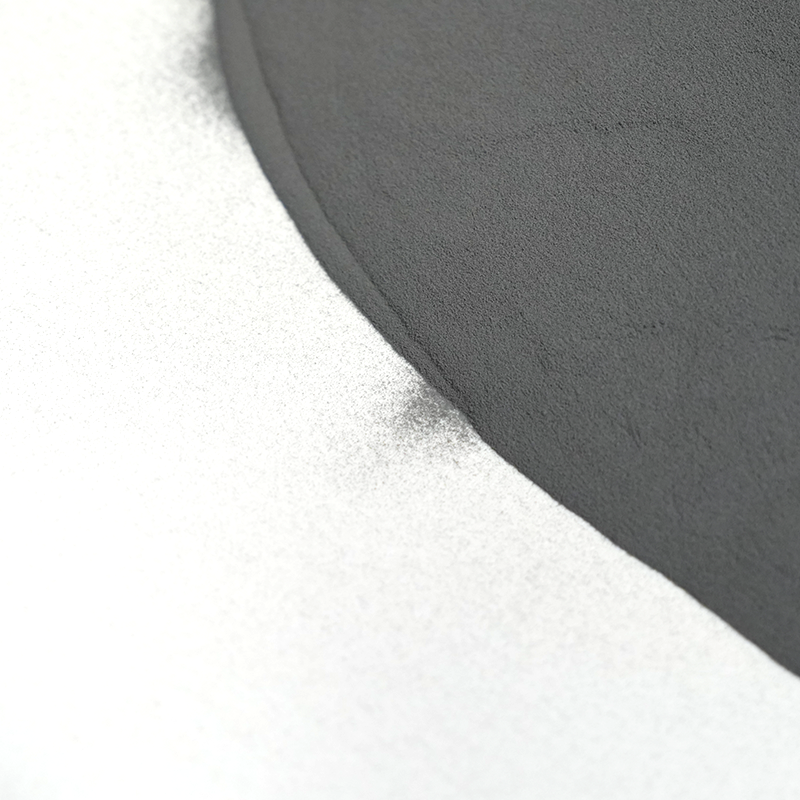

Tungsten carbide is a fascinating material, known for its exceptional hardness and durability. To truly understand its value, let's explore the physical and chemical properties that make WC powder so unique and essential for various industrial applications.

Physical Properties: The Strength of Tungsten Carbide

The physical properties of tungsten carbide are what give it its legendary reputation.

-

Hardness: Tungsten carbide is one of the hardest materials known to man, second only to diamond. Its hardness typically measures between 9 and 9.5 on the Mohs scale. This extreme hardness is why it's so effective in cutting tools, armor-piercing ammunition, and other wear-resistant components. The ability to resist abrasion is a key feature of this hard metal powder.

-

High Melting Point: With a melting point of around 2870°C (5200°F), tungsten carbide can withstand incredibly high temperatures. This property makes it a top choice for applications in high-temperature environments, such as jet engines and furnace components, where other materials would fail.

-

High Density: Tungsten carbide has a very high density, approximately 15.63 g/cm³. This is about twice the density of steel and similar to that of gold. This high density contributes to its significant mass and robustness, making it suitable for applications like weights, counterweights, and ballistic inserts.

-

Excellent Compressive Strength: This refractory metal powder exhibits outstanding compressive strength, meaning it can withstand immense forces without deforming or cracking. This property is particularly crucial in applications like rock drills and stamping dies, where the material is subjected to extreme pressure.

Chemical Properties: Stability and Corrosion Resistance

The chemical properties of tungsten carbide complement its physical strength, ensuring its longevity and performance in challenging environments.

-

Chemical Stability: Tungsten carbide is remarkably stable and generally unreactive. It doesn't readily react with most acids or bases at room temperature, which is a major advantage. This chemical inertness allows it to maintain its structural integrity in corrosive environments. However, it can be oxidized at high temperatures.

-

Corrosion Resistance: This carbide material shows excellent resistance to corrosion, especially when compared to many metals. This resistance makes it ideal for use in chemical processing, oil and gas exploration, and other industries where components are exposed to corrosive fluids and gases.

-

Brittle Nature: While incredibly hard and strong, pure tungsten carbide is brittle. This is a crucial property to consider. To mitigate this brittleness and improve its toughness, it is typically mixed with a binder metal, most commonly cobalt, to form a composite known as cemented carbide or hardmetal. The cobalt acts as a tough, ductile matrix that holds the hard tungsten carbide grains together, preventing them from fracturing.

The combination of these properties is what makes tungsten carbide powder such a versatile and indispensable material. From manufacturing robust cutting tools to creating durable wear parts, its unique physical and chemical characteristics ensure its continued importance across countless industries.

English

English русский

русский عربى

عربى