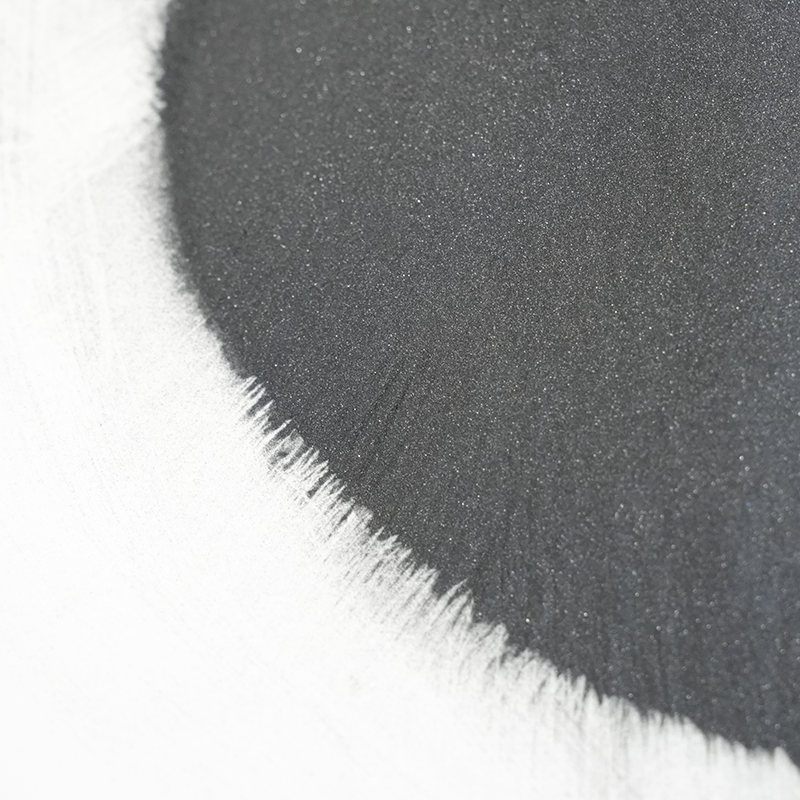

In the relentless pursuit of materials that can withstand the most punishing conditions, carbide composite powders have emerged as a cornerstone of modern industrial technology. These aren’t just simple mixtures; they are meticulously engineered materials that combine the best properties of two distinct phases: an ultra-hard ceramic carbide and a tough, metallic binder. This unique marriage of strength and ductility allows them to excel in applications where traditional materials fail.

The Anatomy of a Carbide Composite Powder

At its core, a carbide composite powder consists of two main components:

-

The Carbide Phase: This is the hard, ceramic component responsible for providing exceptional wear resistance, hardness, and high-temperature stability. The choice of carbide is critical and depends on the specific demands of the application.

- Tungsten Carbide (WC): The most common and widely used carbide. Known for its extreme hardness and good toughness, it is the foundation of cemented carbides (hardmetals) used in cutting tools and wear parts.

- Chromium Carbide ($Cr_3C_2$): Valued for its excellent corrosion and oxidation resistance, particularly at elevated temperatures. It is a go-to choice for protective coatings in corrosive and high-heat environments.

- Titanium Carbide (TiC): Offers a combination of high hardness and lower density compared to WC. It’s often used in cermets and cutting tools to improve resistance to crater wear.

- Other Carbides: Carbides like vanadium carbide (VC), niobium carbide (NbC), and tantalum carbide (TaC) are also used to impart specific properties, such as grain growth inhibition.

-

The Metallic Binder Matrix: This is the tougher, more ductile component that holds the carbide particles together. The binder prevents the brittle failure often seen in monolithic ceramics, providing the crucial toughness and impact resistance needed for real-world applications. Common binders include cobalt (Co), nickel (Ni), and nickel-chromium (NiCr) alloys. The binder content can be carefully controlled to tailor the final properties, with a higher binder content generally leading to increased toughness at the expense of some hardness.

Key Advantages and Applications

The synergistic combination of carbide and binder grants carbide composite powders a range of superior properties, making them indispensable in various industries:

- Exceptional Hardness and Wear Resistance: The hard carbide particles resist abrasion and erosion, while the binder provides support and prevents chipping. This makes them ideal for manufacturing components that face constant friction and wear.

- High-Temperature Stability: Many carbide composites maintain their mechanical integrity at high temperatures, making them perfect for hot gas environments and other extreme conditions.

- Corrosion and Oxidation Resistance: By choosing the right carbide and binder (like chromium carbide with a NiCr binder), these powders can be engineered to resist chemical attack and high-temperature oxidation.

- Improved Toughness: Unlike pure ceramics, the metallic binder provides a mechanism for plastic deformation, preventing catastrophic brittle fractures. This is a critical advantage in dynamic applications.

These properties translate into a wide range of critical applications:

- Thermal Spray Coatings: Used to apply wear, corrosion, and erosion-resistant layers to components in industries such as aerospace, oil and gas, and power generation. Processes like High-Velocity Oxygen Fuel (HVOF) spraying are commonly used to apply these powders.

- Cutting Tools: The extreme hardness of carbide composite materials is fundamental to the production of durable and effective cutting tools for machining metals and other hard materials.

- Hardfacing and Welding: Used to create durable surfaces on new components or to repair worn-out parts, extending their service life significantly.

- Powder Metallurgy: As raw materials for pressing and sintering into solid components like dies, molds, and wear-resistant parts.

A Look Towards the Future

The field of carbide composite powders is not static. Ongoing research is focused on developing new compositions, refining particle morphologies, and exploring novel manufacturing techniques. The drive for materials with even higher performance, greater efficiency, and better sustainability ensures that carbide composite powders will remain at the forefront of materials science innovation, enabling the creation of the next generation of durable, high-performing industrial components.

English

English русский

русский عربى

عربى